View Mobile Number

Copper Alloys

Leading Manufacturers, Wholesaler and Trader of C15000 Zirconium Copper, C18000 Copper Chromium Nickel Silicon, C18150 Copper Chromium Zirconium, C18200 Chromium Copper, C70600 Copper Nickel Tube, C71500 Copper Nickel alloy and Round C11000 Electrolytic Tough Pitch Copper Rods from Mumbai.

| Business Type | Manufacturer, Supplier, Trader |

| Material | Copper |

| Finishing | Polished |

| Shape | Round |

| Application | Industrial |

| Grade | Chromium Copper |

| Type | Chromium Zirconium Copper |

| Country of Origin | India |

The C15000 Zirconium Copper is the alloy with high softening temperature, which makes it good welding material. The addition of zirconium increases the strength of alloy and raises its softening temperature. The increased strength and softening temperature makes the alloy suitable for adapters, power semi conductor bases, spot welding electrodes and connectors.

Applications:

- CONSUMER : Pencil-type & Light Soldering Guns: Tips, Rod Extensions

- ELECTRICAL : Switches, Commutators, Resistance Welding Electrodes, Circuit Breaker Switches, Stud Bases for Power Transmitters & Rectifiers

- INDUSTRIAL : Resistance Welding Tips, Welding Wheels, Connectors, Solderless Wrapped

| Business Type | Manufacturer, Supplier, Trader |

| Material | Copper Nickel |

| Surface Finishing | Polished |

| Color | Brown |

| Feature | Cost Effective, Dimensional, Hardend & Temper |

| Type | Copper Nickel Alloys |

| Country of Origin | India |

Spec Equivalents: RWMA Class III

The C18000 Copper Chromium Nickel Silicon is the copper base alloy which is heat treatable, high in strength and conductivity. The properties of this alloy can fairly be obtained after its heat treatment. The alloy is rich on properties like high hardness, strength and wear resistance with relatively high electrical and thermal conductivity.

Applications:

- Resistance Welding Tips, Wheels and Fixtures

- Stud Welding Collets and Tips

- Sprue Bushing

- Cavities for Injection Molds

- Hot runner Systems for Injection Molds

- Welding Dies for Wire and Flash

- Blow Pins

- Pinch Offs

- Mold Cavities for Bold Molds

- Blow Pins

- Pinch Offs

- Mold Cavities for Bold Molds

- Cores, Core and Ejector Pins for Injection Molds

- Plunger Tips for Metal Die Casting Machines

- Heat Sink Inserts in Steel Plastic Molds

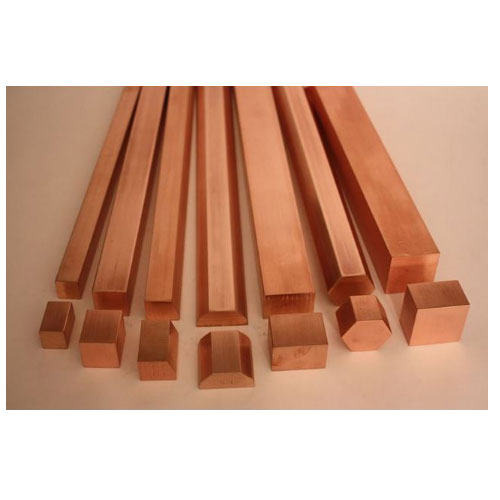

| Business Type | Manufacturer, Supplier, Trader |

| Material | Copper |

| Grade | Superior |

| Purity | 100% |

| Technics | Castings |

| Color | Light Brown |

The C18150 Copper Chromium Zirconium is the copper alloy that is less sticky and resist deformation in comparison to other copper chromium alloys. The alloy is mainly used in cap style resistance welding electrodes and is highly recommended for cold as well as hot rolled spot and seam welding.

Applications:

- Consumer Applications : Pencil-type & Light Soldering Guns: Tips, Rod Extensions

- Electrical Applications : Resistance Welding Electrodes

- Industrial Applications : Welding Electrodes, Welding Wheels, Tips and Rod Extensions

| Business Type | Manufacturer, Supplier, Trader |

| Material | Copper |

| Grade | Superior |

| Purity | 100% |

| Technics | Castings |

| Country of Origin | India |

| Color | Light Brown |

Spec Equivalents: RWMA Class II

The C18200 Chromium Copper is high on conductivity copper alloy that have properties for both cold as well as heat treatment. The alloy is high in strength and hardness and is resistant towards softening at high temperatures. The alloy is mainly used for electrical welding applications where deformation resistance is required at high temperatures.

Applications:

- Consumer Applications : Pencil-type & Light Soldering Guns: Tips, Rod Extensions

- Electrical Applications : Switch Contacts, Electric Motor and Generator Components, Contacts, Wire, High Temperature, Semi Conductor Bases, Parts for Electronic Devices, Cable, Connectors, Thermal Conductors Requiring Greater Strength than Copper, Switch Gears, Electrical Connectors, Electrical Conductors Requiring Greater Strength than Copper, Arcing and Bridging Parts, Circuit Breaker Parts, Electron Tube Grid Side Rods

- Industrial Applications : Seam Welding Wheels, Electrode Holder Jaws, Flash Welding Electrodes, Plastic Mold Components, Resistance Welding Machine Electrodes, Flash Welding Electrodes, Current Carrying Shafts and Arms, Wear Plates on Heavy Equipment, Heat Sinks, Structural Parts, Spot Welding Tips, Molds

| Business Type | Manufacturer, Supplier, Trader |

| Material | Copper |

| Shape | Round |

| Color | Light Brown |

| Condition | New |

| Type | Cupro Nickel Tubes |

| Country of Origin | India |

The C70600 Copper Nickel is the alloy that offer corrosion resistance in salt water environments. The alloy contains 10-30 percent of nickle with addition of iron and manganese, which are necessary to maintain resistance towards corrosion.

Typical Uses for C70600 Copper Nickel "90/10":

- AUTOMOTIVE : Power Steering Tube, Brake Lines

- CONSUMER : Screw Lamp Bases

- INDUSTRIAL : Condenser Plates, Condensers, Weld Torch Tips, Heat Exchanger Tubes, Valve Bodies, Evaporator Tubes, Pressure Vessels, Distiller Tubes, Pump Impellers for Oil Refining, Ferrules, Evaporators

- MARINE : Boat Hulls, Tube Sheet for Salt Water Service, Salt Water Pipe Fittings, Salt Water Piping Systems, Salt Water Piling Wrap, Hot Water Tanks, Salt Water Baffles, Propeller Sleeves, Ship Hulls, Water Hoses

- PLUMBING : Flanges

| Business Type | Manufacturer, Supplier, Trader |

| Material | Copper Nickel |

| Surface Finishing | Polished |

| Color | Brown |

| Feature | Corrosion Resistance, Cost Effective, Dimensional |

| Type | Copper Nickel Alloys |

| Country of Origin | India |

Spec Equivalents: ASTM B151, MIL C15726F

The C71500 COPPER NICKEL "70/30" alloy is the corrosion resistant alloy mainly used in salt water environment. The alloy is the combination of nickle, iron and manganese that helps in maintaining good corrosion resistance and is commonly used in valves, and pump components.

Applications:

- Industrial Applications : Pump Impellers, Heat Exchanger Tubes, Evaporator Tubes, Distiller Tubes, Condenser Plates, Refrigerators, Process Equipment, Condenser Components, Ferrules, Welding Backing Rings, Flexible Metal Hose, Weld Wire, Boiler Parts, Condensers, Propeller Sleeves, Heat Exchanger Components

- Marine Applications : Salt Water Flanges, Salt Water Piping, Valve Bodies, Sea Water Service, Fittings, Sea Water Condensers, Salt Water Pipe Fittings, Water Boxes - Salt Water Applications, Pump Bodies and Internal Parts-Sea Water

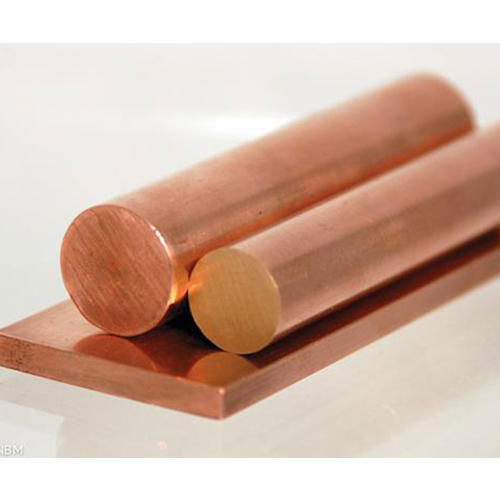

| Business Type | Manufacturer, Supplier, Trader |

| Material | Pure Copper |

| Textures | Solid |

| Shape | Round |

| Color | Brown |

| Certification | ISI Certified |

| Feature | Corrosion Proof, Excellent Quality, Fine Finishing |

| Type | Copper Rods |

| Country of Origin | India |

Spec Equivalents: CDA 110 ETP, ASTM B124, ASTM B152, ASTM B187, ASTM B188, ASTM B272

The electrolytic tough pitch copper is the copper with high thermal and electrical conductivity. The products manufactured using this copper possess good corrosion resistance and soldering ability. The inherited fabrication qualities of the copper allows it to bend, drilled, soldered, riveted and to be fit in to almost any design specifications. This variant of copper has excellent hot workability.

Applications:

- Electrical Industry

- Telecommunications Industry

- Architectural Industry

- Antimicrobial Applications